Installing hardwood floors is a great way to increase your home’s value – and catch the interest of prospective home buyers. Although wood floors are generally more expensive to buy and install than carpet or vinyl, they lasts for decades. Before you set out to shop for your new floor, be sure to refer to our guide.

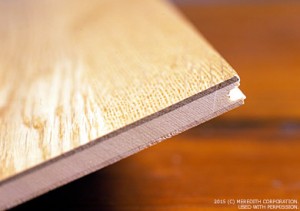

Solid wood flooring is made from one continuous piece of wood. Most is 3/4 inch thick. When you look crosswise at a piece of solid flooring, you may see growth rings or striations, but there are no layers or ply. Wood strips are anywhere from 1-1/2 inches to about 2-1/4 inches wide. Planks are wider than 2-1/4 inches. Most strip and plank flooring is milled with tongue-and-groove edges so boards will fit together, but some planks are flat-edged for a more rustic look.

Types of wood: The hardest species are hickory, pecan, hard maple, and white oak. Next on the list: white ash, beech, red oak, yellow birch, green ash, and black walnut. Cherry and mahogany are softer, but still make gorgeous and durable floors. Pine is a softwood, so it may dent and ding, but for many homeowners, that adds to the floor's charm. And, like hardwoods, pine should last the lifetime of your home. Southern yellow pine is the hardest pine and is recommended for higher-traffic areas. Heart pine, from the center section of old-growth Southern longleaf yellow pine, is difficult to come by and expensive, but some experts say heart pine rivals red oak in hardness. Pine flooring is often sold in widths from 4 to 16 inches to simulate what was used in Colonial-era homes.

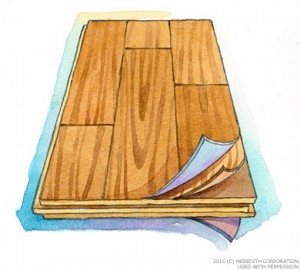

Engineered wood flooring is made from layers of wood stacked and glued together under heat and pressure. There are usually three or five layers stacked with grains running perpendicular to each other. All wood expands and contracts with heat and humidity, but engineered wood is more dimensionally stable because the layers keep the movement in balance.

Engineered wood flooring is made from layers of wood stacked and glued together under heat and pressure. There are usually three or five layers stacked with grains running perpendicular to each other. All wood expands and contracts with heat and humidity, but engineered wood is more dimensionally stable because the layers keep the movement in balance.

Because it is less inclined to swell and shrink, engineered wood can be laid in areas where solid wood cannot, such as over concrete or in high-moisture areas.

Salvaged lumber offers an aged and distressed look. Antique or recycled lumber involves more labor (removing from old buildings, pulling out nails, drying, etc.). But it can be worth the price if you're hoping to lay a floor that matches an old pine one.

When buying recycled lumber, make sure it has been kiln-dried. Even 150-year-old lumber can still have a high moisture content. Often, flooring planks are cut from old barn beams, and moisture levels can differ in various parts of the beam.

There is no formal grading for antique lumber, but most dealers offer grades depending upon the number of nail holes and other damage. In addition to grade, ask how long the boards are. It can be difficult to get long boards in antique woods, and the look of a floor made up of 3-, 4-, and 5-foot lengths is much different than one with boards that are 8 or 16 feet long.

Parquet floors are made from custom-crafted wood tiles that are used to create a patterned floor.

Wood-look laminate flooring is made to look like wood, but the decorative layer is actually a photograph. Most laminates have four-ply construction: a backing or balancing layer, a moisture-resistant wood-based core of high- or medium-density fiberboard, a decorative layer, and a wear-resistant layer of melamine resins. Flooring laminates are similar in concept to laminate countertops, but the wear layer is strengthened by hard particles.

Because laminates are only about 1/3 inch thick, they can be installed over nearly any kind of subfloor -- vinyl, concrete, wood. They're also extremely durable, with the ability to resist high heels, pet claws, and cigarette burns, making them well-suited for high-traffic areas, busy family kitchens, and homes with children and pets. Although laminates cannot be refinished as wood can, damaged planks can be replaced, and some manufacturers sell a putty for repairs.

A factory finish -- usually four or more coats of ultraviolet-cured urethane resins -- is one that the manufacturer applies at the plant. Because the finish is applied under strict environmental controls, manufacturers say it is more consistent and durable. Factory-finished floors can be installed right out of the box, making them wonderfully pain-free when you are trying to live in a house where the floors are being replaced. There are many different stain colors and finishes to choose from.

On-site finishing allows the builder to custom-fit and finish your floor to the space. Many flooring professionals maintain that the smoothest finish can be achieved by sanding and finishing a floor on site. Custom finishing gives more versatility in colors, too. You do have to put up with the messy and time-consuming tasks of repeated sandings and finish applications.

What Type of Finish Is Best?

Surface finishes, usually polyurethane, form a protective layer over the wood and are used on all factory-finished and most site-finished floors. Increasingly, water-based polyurethanes are applied on site-finished floors. They are quick-drying, with little odor, and more environmentally friendly. The newest water-based polyurethanes rival oil-modified polyurethanes in durability. Also, water-based products will not develop an amber hue over time, as oil-modified finishes do.

Penetrating finishes are oils and waxes that penetrate the surface of the floor and form a protective coating. If you can run your hand across the floor and feel the grain, a penetrating finish was used. Pine floors that have an antique look are often finished with tung oil, which gives a satin or slightly worn matte patina. Tung oil used on floors today is usually a special mixture that includes resins, making it harden into a tough protective surface.

Wood and laminate floors are sold by the square foot. Figure the size of your room plus a 10 percent waste factor. (Installers will need to measure the space before you order.) Installation costs for wood and laminates are comparable, about $3 to $4 a square foot. A factory-finished floor will cost more for the wood itself, but generally the higher labor and installation charges involved in finishing a raw floor will make the two quite comparable.

Wood and laminate floors are sold by the square foot. Figure the size of your room plus a 10 percent waste factor. (Installers will need to measure the space before you order.) Installation costs for wood and laminates are comparable, about $3 to $4 a square foot. A factory-finished floor will cost more for the wood itself, but generally the higher labor and installation charges involved in finishing a raw floor will make the two quite comparable.

Site-finished wood: A standard solid strip floor, such as red oak, is about $8 per square foot for materials, installation, and site finishing. Solid, wide pine planks range from $6 to $12 installed.

Factory-finished wood: Factory-finished, engineered flooring also starts at about $8 per square foot installed, but most are in the $10- to $14-per-square-foot range. Adding a border or inlay design will increase the cost.

Laminate: The price for laminate is $7 to $10 per square foot installed, including foam underlay and glue. Because the design layer is not real wood, the species style (maple, oak, pine, etc.) won't affect the price. Laminates can be installed by a do-it-yourselfer, as well. In that case, you pay only about $4 per square foot for the flooring itself.

Often when renovating an older home, people will tear up carpeting and find lovely hardwood flooring marred by plywood patches and damaged boards.

Refinishing an old floor can be time-consuming but worthwhile.

Refinishing an old floor can be time-consuming but worthwhile.

- One solution is to use matching boards from an adjoining closet or another room. Then lay new flooring in the less conspicuous location.

- Another option is to look for antique or salvaged lumber to match your existing floor.

- If you need to buy new wood to match old, call in an expert. A professional can pull up old boards and weave the new with the old. Blending or "shadowing" with stains can also disguise the differences in wood's age.

- Or don't try to match the woods at all. Use a contrasting border to divide the areas, or announce the difference with an accent strip at a threshold.

Wood floors have come a long way since the days of labor-intensive waxing. These tips will help you keep your wood flooring in tip-top shape.

- New urethane finishes require nothing more than sweeping, and manufacturers advise against using wax products. Simply sweep, vacuum, or dust-mop at least once a week to minimize damage caused by dirt, sand, and grit. (Dirt particles act like sandpaper, scratching and dulling wood floors.)

- Place rugs or floor mats at entrances to trap dirt, and shake them out frequently.

- Use a broom with fine, exposed ends to trap grit.

- When vacuuming, use a brush attachment; beater bars can dent a floor's finish.

- Wipe up spills and foot tracks as they happen. If your finish is in good shape, you can lightly damp-mop the floor using a neutral-pH wood cleaner or products recommended by the flooring manufacturer.

- Urethane-finished floors in high-traffic areas may need to be recoated every 3 to 5 years. This involves cleaning and lightly abrading the old surface before applying fresh coats of urethane. Recoating should be done by a flooring professional.

- Floors treated with a penetrating finish should be swept and kept clear of dirt, also. Tung oil may need to be reapplied every 5 to 10 years, or it can be applied just in high-traffic areas.

- You can wax a floor treated with tung oil. If you do, though, never use water on it, and avoid spills; water will leave white spots. A waxed floor will need to be stripped and rewaxed once or twice a year.

- Don't wear spiky high heels, golf shoes, or any other shoes with exposed nails or cleats. They will likely dent and damage the floor. Put felt contacts under furniture legs to prevent scratches. For the same reason, you might want to be extra-vigilant about trimming your dog's nails regularly.

- Laminates are cared for in much the same way as urethane-finished wood floors. Vacuum or sweep at least once a week. Wipe up spills as they occur, and damp-mop occasionally with manufacturer-recommended products.

Adapted from Better Homes & Gardens. Used with permission. © Meredith Corporation. http://www.meredith.com. All rights reserved.